Oriel Systems (http://www.orielsystems.com) expect that by viewing this site you may well already have knowledge of the telemetry industry and are very likely either a user of remote monitoring systems already or are currently exploring their potential. However, you may be asking yourself, why use Oriel Systems in particular? Let’s start with the basics.

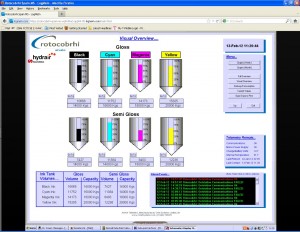

Industrial and commercial companies understand the value of distant monitoring. In an increasingly technical and dissipated engineering, manufacturing and production landscape, having a real time understanding of the front to back process is essential. It could be monitoring sites, silos or feedstock levels or inventory monitoring, but the ability to predict internal and external delivery times have become commercial imperatives for a vast array of applications across the supply chain. This is of particular importance in an evolving and highly technological competitor driven market. Oriel Systems’ telemetry solutions cover a variety of services to meet these needs.

Whether you’re optimising your assets or negotiating a tolling agreement with your financiers, you need to know what’s happening right now. And the devil’s in the details. Stock consumption and relative output formulae used to be a retrospective activity but now with margin’s constantly squeezed it is essential to monitor, and thereby control, the entire value chain.

That’s the basics. But it’s the delivery of the solution to the client that’s important. A global house-hold name in food production doesn’t need to monitor the same things as a chemical giant does, but Oriel Systems provides solutions to them both. Indeed a glance at its prestigious client list will show you the diversity of solutions it provides: http://www.orielsystems.com/client-list.

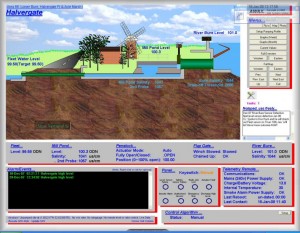

However Oriel Systems also services smaller companies who have telemetry needs which are just as important, and whilst they may not be global or household names like some customers, they none-the-less value the ability to monitor, control and thereby refine and optimise their internal systems.

Why do they use Oriel Systems? (http://www.orielsystems.com). Because its services are tailor-made to suit clients’ specific needs. After all, telemetry isn’t an optional add-on in the production chain; it’s a necessary tool in optimising processes and therefore a direct driver in maximising profit. Despite the industry or scale of the business, all of Oriel System’s clients believe it’s an essential part of the industrial matrix with a direct and calculable impact on the bottom line.

Visit the Oriel Systems website at http://www.orielsystems.com to find out more about how telemetry systems allow you to control both your industrial and commercial processes and, ultimately, your balance sheet.

01249 705070

01249 705070