Removing barriers and increasing accessibility is and always has been the main aim of technology. Indeed, telemetry itself means transmitting data points from a remote location to a central point, increasing operational knowledge and reducing the costs of site visits etc…

It stands to reason then, that accessing data is becoming easier and easier in light of technology, and more specifically the connected internet of things (IoT). A physical machine used to be required to run the software to collect and display the data on a graphical display unit in the office. You had to be in the office to view the data or remotely control a system, and so the scope of telemetry systems, although impressive, was limited to a relatively small number of applications.

This changed over the next few years incrementally with the introduction of remote access viewing applications that could “dial” into the main machine enabling remote viewing of the data and system control from another PC or laptop located elswhere.

In the modern age, access to 4G technology and hosted server applications / software as a service (SaaS) becoming the norm with companies such as Dropbox and Google, the idea of a central control hub seems less important, with secure access being provided remotely through web browsers and native mobile applications.

What this effectively means, is that now, more than any other time before, any type of data gathered is accessible to anyone that requires it, anywhere and in any form. Exciting times lie ahead, as the realms of possibility are only increasing, enabling us to grow and achieve more than has ever previously been possible.

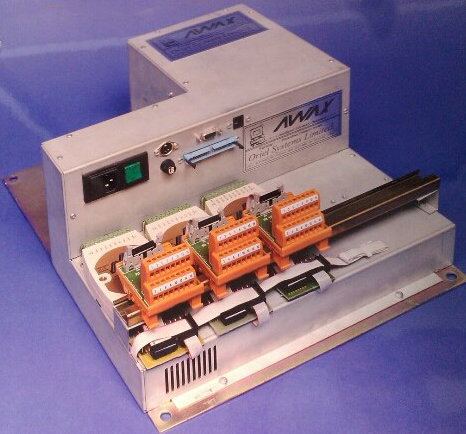

As a telemetry supplier to Internal Drainage Boards across the UK for the last 30 years, Oriel Systems are uniquely placed to give organisations what they need, when they need it, and with significant changes on the horizon (the retirement of PSTN for one), we know what is useful and what is not.

Drainage boards face increasing budget pressures, as well as worsening weather conditions across the globe, meaning that pro actively managing assets is now more important than ever. With an Oriel System, you can ensure that flooding events are strictly monitored and controlled, relieving pressure and stress, whilst at the same time improving working conditions for engineers through a structured and logical working process.

If you have a requirement for remotely controlling assets or receiving data from any source, from levels and temperature monitoring to industrial process control systems, then please get in touch with Oriel Systems Ltd on +44 (0)1249 70 50 70 or visit www.orielsystems.com

01249 705070

01249 705070